Description

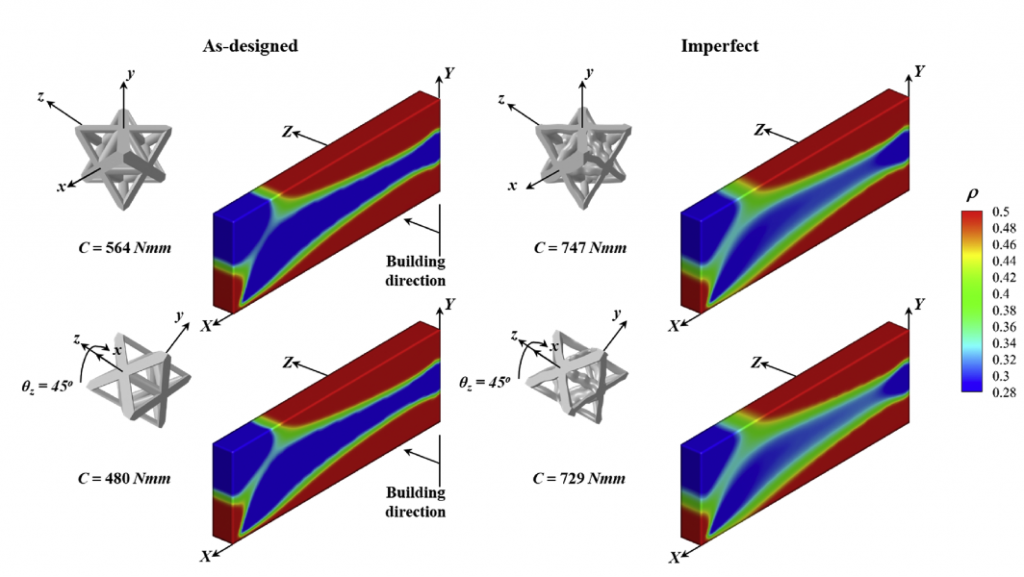

Lattice materials built via additive manufacturing feature geometric and material defects that impact their mechanical properties and optimum design. We are developing methods to integrate them in a density-based formulation for topology optimization of additively built lattice materials, and applying them for the development of structurally optimized technology in multiple sectors.

Some relevant publications

Moussa A, Melancon D, El Elmi A, Pasini D, Topology optimization of imperfect lattice materials built with process-induced defects via Powder Bed Fusion, Additive Manufacturing, Vol 37, 101608, 2021.![]()

Moussa A, Rahman S, Xu H, Tanzer M, Pasini D, Topology optimization of 3D-printed structurally porous cage for acetabular reinforcement in total hip arthroplasty, Journal of the Mechanical Behavior of Biomedical Materials, Vol. 105, 103705, 2020. ![]()

Rahimizadeh A, Nourmohammadi Z, Arabnejad S, Tanzer M, Pasini D, Porous architected biomaterial for a tibial-knee implant with minimum bone resorption and bone-implant interface micromotion, Journal of the Mechanical Behavior of Biomedical Materials,Vol. 78, pp. 465, 2018. ![]()

Arabnejad S, Johnston B, Tanzer M, Pasini D, Fully Porous 3D Printed Titanium Femoral Stem to Reduce Stress-shielding Following Total Hip Arthroplasty, Journal of Orthopaedic Research, Vol 35 (8), 1774-1783, 2017. ![]()

Arabnejad S, Johnston RB, Pura JA, Singh B, Tanzer M, Pasini D, High-Strength Porous Biomaterials for Bone Replacement: a Strategy to Assess the Interplay between Cell Morphology, Mechanical Properties, Bone Ingrowth and Manufacturing Constraints, Acta Biomaterialia 30: 345–356, 2016. ![]()