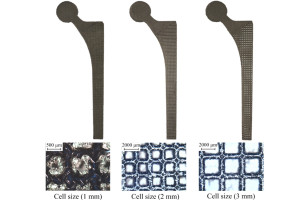

Fabricated 2D Ti6Al4V Cellular Implants |

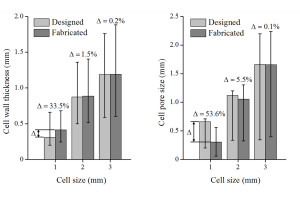

EBM Manufacture versus Nominal Design |

Description

As described in the project Hip Replacement Implants (Research Track 2), we have developed a material with a tailored microlattice that is isoelastic, i.e. stiffness properties are balanced and the strain energy mechanically matches that of the host bone tissue. We have successfully demonstrated that Electron Beam Melting (EBM) can be used to build Ti-6Al-4V graded microlattices that possess minute structural details. However, Scanning Electron Microscopy has shown a limitation in the EBM process: a morphology mismatch has been observed between as–designed and as-built Ti-6Al-4V microlattices. This project focuses on the EBM manufacturing of open-cell, graded Ti-6Al-4V microlattices. The objective is to establish a robust protocol for Ti-6Al-4V microarchitecture manufacturing to accurately reproduce morphological and mechanical properties of the microlattice. The specific goals are: 1) to determine the manufacturing limits of EBM in building Ti-6Al-4V microgeometry with prescribed pore topology, size and strut thickness; and 2) to calibrate a protocol for EBM manufacturing that successfully reduces the mismatch between as-designed and as-produced microlattices. While this project is currently geared toward hip replacement implants, the outcome can be used for any other type of microlattice prosthesis used in reconstructive orthopedics.

Current Students

Burnett Robert Johnston, Baljinder Singh

Relevant Publications

- Khanoki Sajad A., Pasini, D., Fatigue design of a mechanically biocompatible lattice for a proof-of-concept femoral stem, Journal of the Mechanical Behavior of Biomedical Materials, Vol. 22, pp. 65-83, 2013. link to PDF